Inside Angle 33: More than just thermals

How it all started

Matt Baack’s 18 years of concrete experience started with a college construction job. Full of youthful ambition and a world of possible career paths, he was repeatedly advised by his older colleagues to get out of concrete and “stay in college”. He graduated with a degree in history and *spoiler alert* was all too eager to disregard their advice.

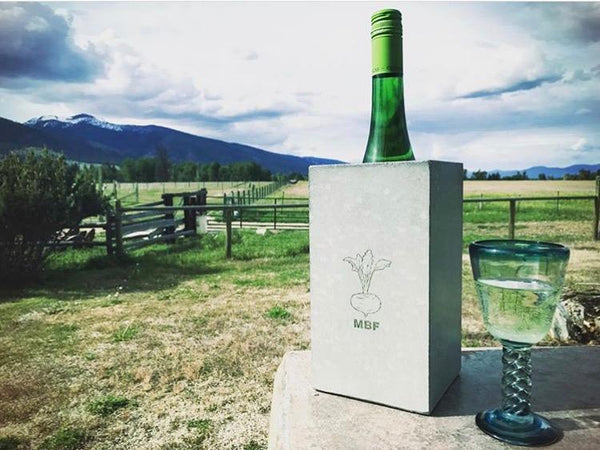

He now considers himself a “Concrete Transformer” of sorts, figuring out how to turn concrete, a traditionally functional and un-aesthetically pleasing material, into art.

Angle 33 is all about enjoying the details of life and using concrete as a unique medium to make a functional and eye-catching statement.

“People don’t mass produce concrete because it’s so touchy”, Matt pointed out. Each batch of concrete comes out different and the slightest variation in temperature or timing can throw it all off. “That’s why everything we do is custom made.”

All custom everything

Almost everything about the Angle 33 shop was created through trial and error. Five years of work has gone into perfecting and streamlining each of the 13 steps in the personalized production process.

Matt custom made a convection oven for the shop, specially designed to hold drying molds at a consistent temperature in the changing Montana elements. He again used trial and error to create a “cementitious material” recipe that produces any set number of thermals, planters or coasters. So he can operate as leanly as possible and minimize wasted material. That hand-written list of recipes dutifully hangs in the Angle 33 mixing room.

It’s a lot of work, but that’s what it takes to achieve perfection.

Of course, with trial and error comes a good sense of humor, and the humorous labels and notes spread around the shop is a pure testament to Matt’s work style. The “grinding station”, where freshly molded products are smoothed down, is labeled with an important specification: “not the dance move”. The packaging dispenser is labeled with a prestigious claim: “the most hi-tech dispenser known to man”.

There simply is never a dull moment at the Angle 33 shop.

Keeping it local

Matt sees tremendous value in working with local businesses to create new products. His latest creation is a four-pint beer thermal he developed with Draught Works Brewery in Missoula, MT.

“These businesses know what is going to work,” Matt said on the importance of his partnerships. He is able to use their knowledge of what the end customer is looking for to make changes to his designs and brainstorm new products. That’s the power of local.

While Angle 33 products are sold all across the country, Matt has a strong dedication to keeping production as locally integrated as possible. Even Angle 33’s packaging materials are made in Montana. He purposefully does this to support, “the families of those with whom we work and share our community.”

Angle 33 is so much more than a concrete thermal company. It’s a locally motivated community member. It’s a hard-working and perfection-seeking innovator. It’s a continuous learning experience built on 18 years of passion for an underrated material. But most of all, Angle 33 is an art.Leave a comment

Comments will be approved before showing up.

Also in News